Introduction

Materials and Methods

Plant material

Packaging material

Storage condition and investigated items

Analysis of sensory quality and internal qualities

Analysis of color and soluble solids content

Changes in gas content of different packaging films

Statistical Analysis

Results and Discussion

Fresh weight and sensory quality

Changes in internal qualities and color

Changes in gas concentration of different packaging films

Conclusion

Introduction

Asparagus (Asparagus officinalis L.) has been used as a vegetable and in medicine for a long time. There has been an increase in asparagus production and consumption because of its highly nutritional and economical values. As of 2016, Korean cultivation acreage for asparagus had increased to 55.4 ha (Rural Development Administration, 2016).

The green asparagus spear is an immature vegetative tissue that maintains a high respiration rate and physiological activity after harvesting, which can lead to perishability. Although asparagus is a non-climacteric vegetable (Zhang et al., 2012), the changes in contents of CO2 and O2 could affect the shelf life and nutritional value during cold storage. Low O2 content inside packaging, along with the high respiration rate of asparagus, can lead to an off-odor (Gariepy et al., 1991). The CO2 content affects not only the respiration-related metabolism but also secondary metabolism (Watkins et al., 1999). Sanchez-Ballesta et al. (2007) confirmed that a short-term high CO2 treatment at low temperature could maintain the quality and prolong the shelf life of some table grape cultivars during storage. Bacteria and mold growth on fruit and vegetables is inhibited by CO2 (Mattos et al., 2012). Additionally, CO2 is beneficial for vegetable preservation by controlling postharvest decay (Holcroft and Kader, 1999), firmness (Chen et al., 2009), and color change (Siomos et al., 2010). An optimum level of CO2 is helpful for keeping produce fresh by reducing physiological activities such as respiration and ethylene production (Bhowmik and Matsui, 2004).

To learn how to prolong the shelf life and maintain the quality of asparagus during postharvest storage, many studies have been conducted to identify the most effective storage methods, such as controlled atmosphere (CA) (Lee, 1981), modified atmosphere (MA) (Gariepy et al., 1991) and hot water pretreatment (Yoon et al., 2018). Of these, MA storage slows down the respiration rate and other metabolic processes, inhibits pathogen development (Kahramanoğlu, 2017), has a low processing cost and is easy to apply (Yoon et al., 2017). Often, CO2 is used as a flushing gas in MA packaging (Mattos et al., 2012). The optimal concentration of CO2 is 5-12% and the suitable concentration of oxygen is 5% or higher in most cases (Kader, 2002).

In previous studies, we observed that the application of different oxygen transmission rate (OTR) film treatments at low temperature maintained the quality and prolonged the shelf life of green asparagus spears during postharvest storage. However, the effect of elevated CO2 on green asparagus spear freshness quality, shelf life, and physiology during postharvest storage is still unclear. The objective of this study was to characterize the influence of high CO2 (60%) treatment on asparagus spears during postharvest storage.

Materials and Methods

Plant material

Asparagus spears (Asparagus officinalis L. cv. Welcome) were cultivated in the open field in Yanggu-gun, Gangwon-do, Korea. The asparagus spears with a 1.4 ± 0.1 cm diameter and 24 ± 1.0 cm lengths were selected for this study in May 2019.

Packaging material

Five different kinds of packaging materials including perforated film (P), microperforated film (MP, 48 holes perforated by drilling 0.6 mm diameter), oxygen transmission rate (OTR) films of 1,300 and 10,000 cc/m2/day/atm (1,300 cc and 10,000 cc), and vacuum film (V) were used to investigate their efficiency in postharvest storage. Additionally, a treatment of 60% carbon dioxide (V + 60% CO2) injected into the vacuum film was conducted.

Storage condition and investigated items

All experimental groups were stored at 2 ± 1°C with a relative humidity of 85 ± 5%. Fresh weight, the concentrations of CO2, O2, and C2H4 in packages, and visual quality were measured every 5 days. Soluble solids, hue angle, firmness, and off-odor were also checked on the initial day and final day of storage.

Analysis of sensory quality and internal qualities

Fresh weight loss rates were measured according to the following formula:

| Fresh weight loss rate = (initial fresh weight-final fresh weight) / initial weight × 100% | (1) |

Five skilled panelists assessed the visual quality and impairment of asparagus during cold storage and on the final storage day according to the methods of Choi et al. (2015). Asparagus visual quality was assessed on a scale of 1 to 5 (1= worst, 2= bad, 3= good, 4= better, 5= best), and off-odor was assessed on a scale of 0 to 5 (0= no off-odor and 5= strong off-odor). Asparagus spears with a visual quality score equal to or greater than 3 and an off-odor score of less than 3 were determined to be suitable for sale.

The firmness of asparagus tips (from topmost 5 cm) and stems (from lowermost 8 cm) was measured by rheometer (Compac-100, Sun Scientific Co. Led., Japan) with a probe (Ø 3.0 mm) at 1.0 mm/sec speed.

Analysis of color and soluble solids content

The hue angle of asparagus spears was measured using a color-difference meter (Model CR-400, Konica Minolta Sensing, Inc., and Japan). Soluble solids content was measured by a pocket refractometer (PAL-1, Atagi, Japan).

Changes in gas content of different packaging films

Carbon dioxide (CO2) and oxygen (O2) concentrations in the different treatments were measured with an infrared CO2/O2 analyzer (Model Check Mate 9900, PBI-Dansensor, Ringsted, Denmark) and ethylene concentration was measured by a GC-2010 Shimadzu gas chromatography (GC-2010, Shimadzu Corporation, Japan) (Park et al., 2000).

Statistical Analysis

The statistical characteristics of the data were examined using Microsoft Excel 2016 and IBM SPSS Statistics (Version 24, IBM Corp., Armonk, NY, USA). Significant differences were tested with ANOVA and Duncan’s test at P < 0.05 level.

Results and Discussion

Fresh weight and sensory quality

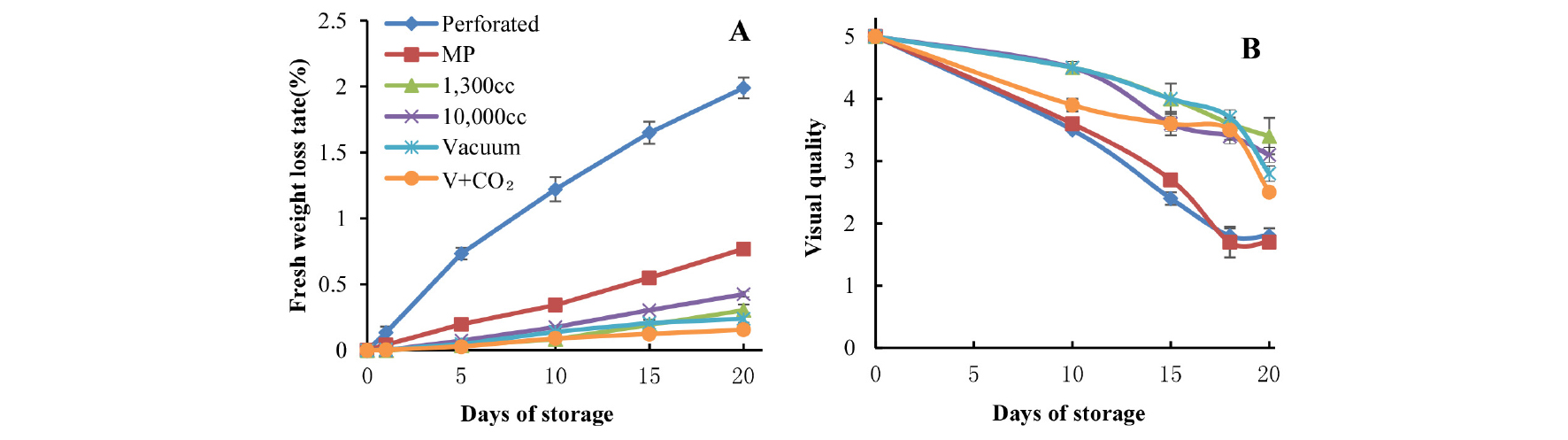

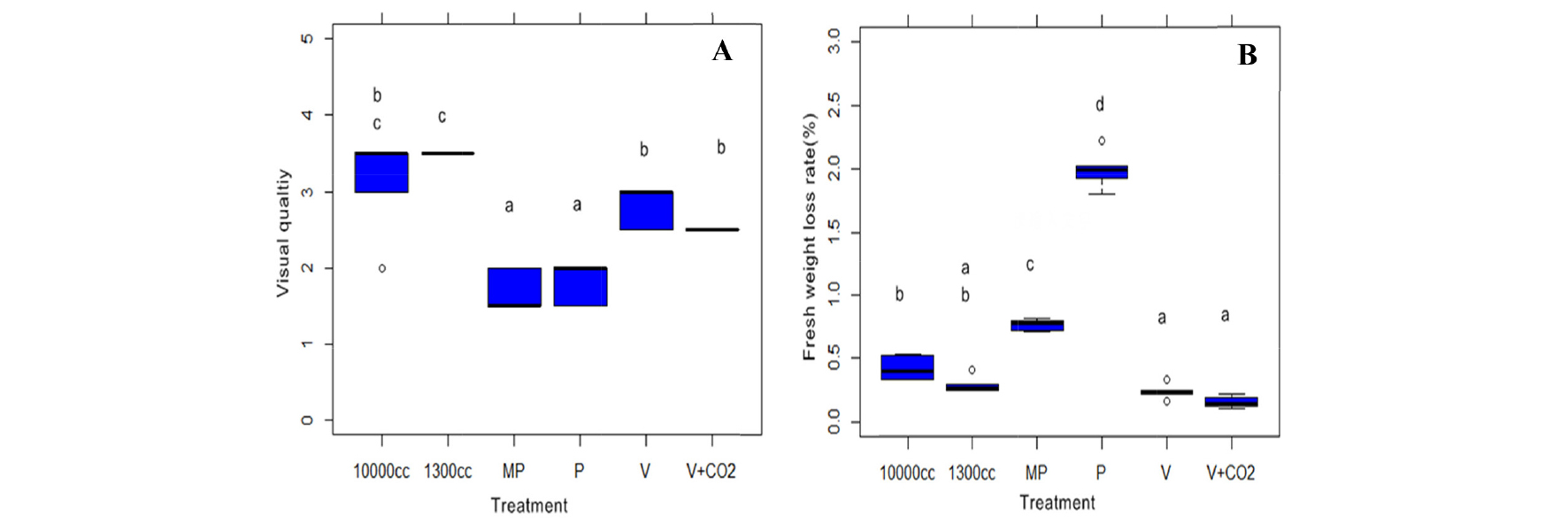

Asparagus spears in all treatment groups lost fresh weight over time (Fig. 1A). There are significant difference among all the treatments (Fig. 2B). Perforated film packaging had the highest fresh weight loss rate of nearly 1.99% by the last storage day. The lowest fresh weight loss rate of less than 0.2% was measured in the V + 60% CO2 treatment. All treatments had fresh weight loss rates less than 2.5%, which is lower than the maximum allowable fresh weight loss rate of 8% for asparagus (Paull and Kays, 2004). It is likely that the lower green asparagus spear fresh weight loss rate is closely related to the relatively high humidity in the packaging because of transpiration inhibition (Lee, 1996). In strawberries, the application of 20% CO2 prevented the movement of water into intercellular spaces and protected the cellular structures (Blanch et al., 2012). The V + 60% CO2 treatment had the lowest fresh weight loss rate compared with the other treatments. We assume that high CO2 application prevented the fresh weight loss, consistent with the findings of Blanch et al. (2012).

Fig. 1.

Changes of fresh weight loss rate (A), visual quality (B) of green asparagus spears treated with the different films and methods. P, Perforated film; MP, micro-perforated film; 1,300 cc, 1300 cc/m2/day/atm oxygen transmission rate (OTR) films; 10,000 cc, 10,000 cc/m2/day/atm oxygen transmission rate (OTR) films; V, vacuum film; V + 60% CO2, 60% CO2 injected into vacuum film, treatments storage for 20 days at 2°C. Vertical bars represent ±SE (n = 5).

Fig. 2.

The significance analysis of asparagus spears visual quality (A) and fresh weight loss rate (B) in the last storage day.

1)P, Perforated film; MP, micro-perforated film; 1,300 cc, 1,300 cc/m2/day/atm oxygen transmission rate (OTR) films; 10,000 cc, 10,000 cc/m2/day/ atm oxygen transmission rate (OTR) films; V, vacuum film; V + 60% CO2, 60% CO2 injected into vacuum film.

2)Vertical bars represent ±SE (n = 5).

3)Different letters indicate that the means are statistically different using the Duncan’s test (P < 0.05).

Visual quality, the most important factor to consumers purchasing asparagus was reduced during storage using all treatments (Fig. 1B). Different treatments showed significant difference (Fig. 2A) Perforated and microperforated film packaging had the lowest level of visual quality. The 1,300 cc and 10,000 cc OTR treatments maintained marketable visual quality (scores ≥ 3) and had the least off-odor on the final storage day. The off-odor was worst in vacuum film and V + 60% CO2 treatments (Table 1). High CO2 concentrations led to the accumulation of fermentation products and affected the acceptability of strawberries (Chen et al., 2009). Tian et al. (2002) found that ethanol production increased when high CO2 treatments were applied to longan fruits causing off-odor and decay.

Changes in internal qualities and color

In addition to the visual quality and off-odor, firmness is another crucial parameter that can negatively affect sale value and shelf life because consumers tend to buy soft asparagus. Our results showed that the firmness of tips and stems increased from the initial storage day to the final storage day (Table 1). Firmness was higher in perforated film and microperforated film treatments and lowest in the V + 60% CO2 treatment. High CO2 could suppress firming of asparagus spears. This is in agreement with studies showing high CO2 and low O2 concentrations could inhibit the energy supply used in cell wall synthesis and spear toughening (Helen et al., 1992). Asparagus spears retain high physiological activity (Heyes et al., 1998) after being harvested; thus, lignification and cellulose content can increase. High CO2 inhibits excessive postharvest accumulation of cellulose and hemicellulose compounds which can cause asparagus spear toughness (Huyskens-Keil and Herppich, 2013). Furthermore, elevated CO2 can inhibit PAL activity (Chen et al., 2009; Holcroft and Kader, 1999), a key enzyme used in lignin synthesis (Bhowmik and Matsui, 2004). In a previous study, the total soluble solids content declined in all treatments during postharvest storage, with the 10,000 cc OTR film treatment yielding the highest content (Yoon and Kang, 2017). In this study, soluble solids were significantly higher in vacuum film and V + 60% CO2 packaging compared to other treatments (Table 1). High CO2 concentrations inhibit respiration, a process which consumes soluble solids. High CO2 concentration substantially lowered sugar consumption (Heyes et al., 1998). A short-term 20% CO2 treatment promoted the accumulation of some nonstructural carbohydrates in grapes (Blanch et al., 2011).

2)Values are presented as means (n = 5).

3)Different letters indicate that the means are statistically different using the Duncan’s test (P < 0.05).

Color change is a major factor in determining the quality of asparagus spears, and stem yellowing is a visual indicator of deterioration during long-term storage (Yoon et al., 2016). The degree of yellowing in asparagus spears is determined by measuring the hue angles (Chang and Kim, 2015). The hue angle values of green asparagus were similar between the initial and final measurements, except in the perforated and microperforated packaging. The perforated film treatment had the lowest hue angle on the final storage day (Table 1). In a previous study, we found that the 10,000 cc OTR treatment was the best treatment for maintaining the color of green asparagus during cold storage. In this study there was no significant difference in the hue angle among the 1,300 cc, 10,000 cc, vacuum film and V + 60% CO2 treatments, although the highest hue angle value occurred in the vacuum film treatment. Kader (2002) reported that the color change or yellowing of some horticultural products was related to aging and ethylene. Asparagus processed with 10 µL/L-1 ethylene led to the reduction of chlorophyll (Lee, 2015). Elevated CO2 can retard the damage caused by ethylene (Yoon et al., 2018), therefore the yellowing of asparagus declined under high CO2 storage. Our results were similar to studies conducted on strawberries during which CO2 treatments inhibited the decrease of hue angles (Li et al., 2018).

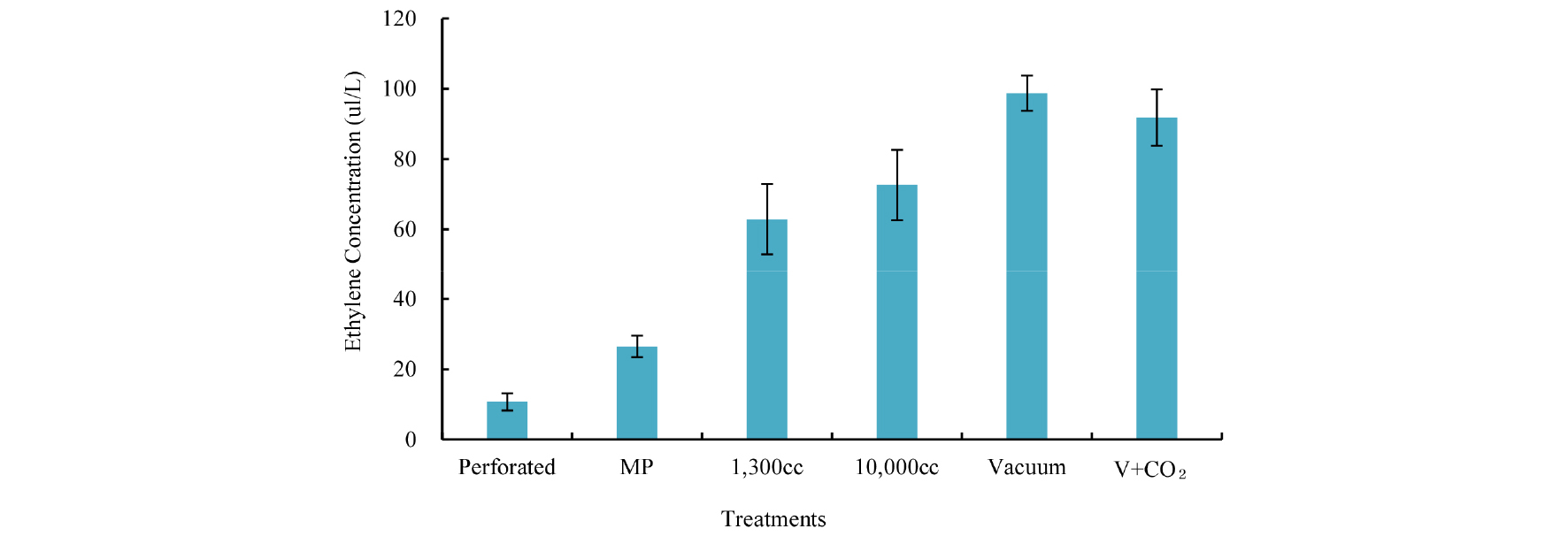

Changes in gas concentration of different packaging films

The concentration of ethylene was elevated compared with the initial day (Fig. 3). Some researchers have shown that wounds can induce the formation of ethylene by activating ACC synthase and ACC oxidase (Kato et al., 2000), both key enzymes in ethylene synthesis and decomposition. Ethylene synthesis is a response of plant tissue to damage (Kato et al., 2000). It is worth noting that the highest C2H4 concentration was detected in the vacuum film treatment because of the low gas transmission rate. Because CO2 is a competitive inhibitor of ethylene (Lee et al., 1996), increasing the CO2 concentration causes a decrease in ethylene. Atmospheric composition in the packaging is important for maintaining the quality and shelf life of green asparagus during long-term storage.

Fig. 3.

Fig. 3. Ethylene (C2H4) concentration in all of the packages treated with the different films and methods. P, Perforated film; MP, micro-perforated film; 1,300 cc, 1,300 cc/m2/day/atm oxygen transmission rate (OTR) films; 10,000 cc, 10,000 cc/m2/day/atm oxygen transmission rate (OTR) films; V, vacuum film; V + 60% CO2, 60% CO2 injected into vacuum film, treatments storage for 10 days at 2°C. Values are presented as means ± SE (n = 5).

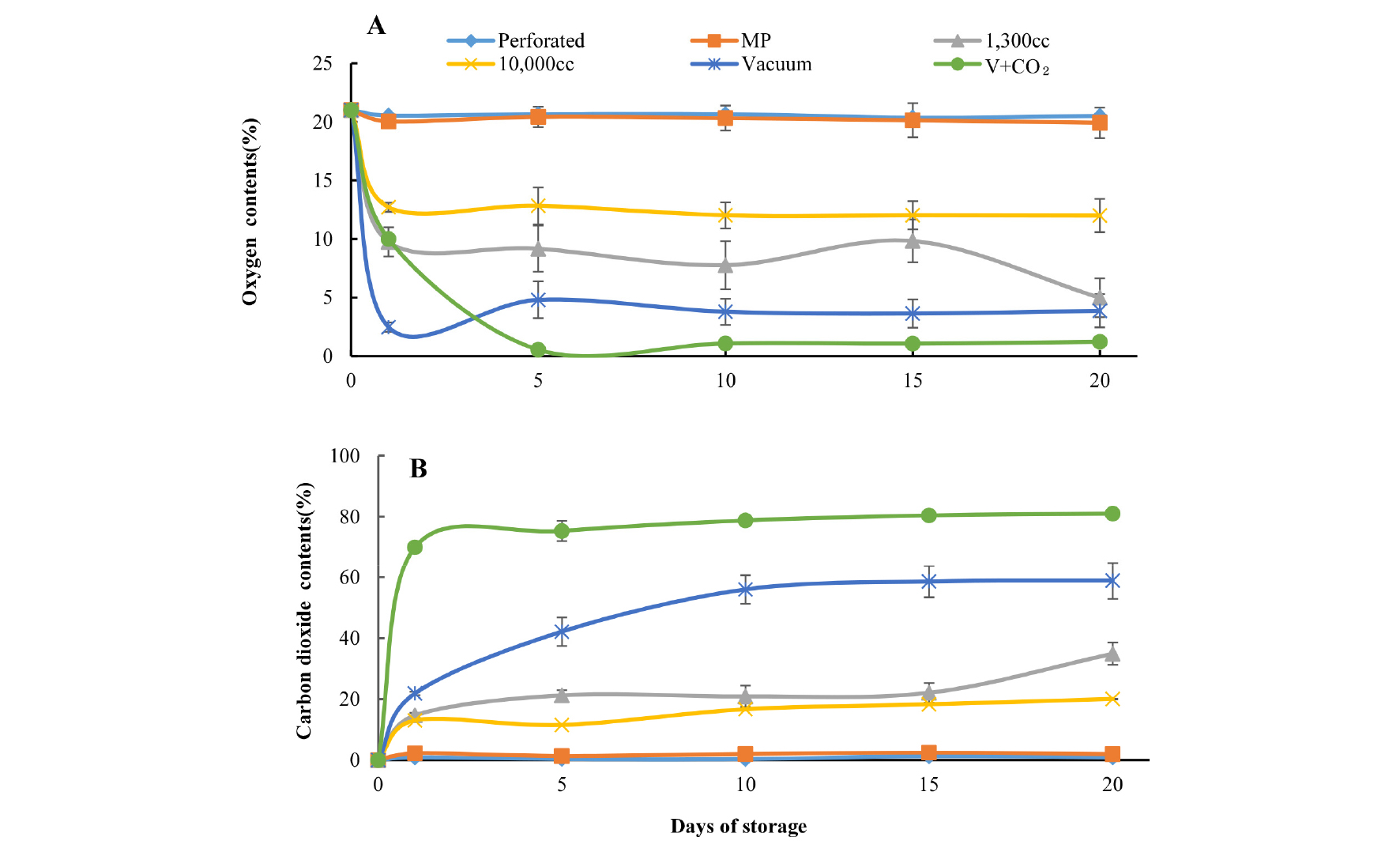

The oxygen contents in all packages, except perforated film and microperforated film, showed a sharp decline after the first storage day (Fig. 4A) but remained stable during the entire cold storage period. The lowest oxygen content, less than 1.5%, was found in the V + 60% CO2 treatment. Some studies have demonstrated that oxygen content less than 3% can lead to deterioration in asparagus quality due to anaerobic respiration (Gariepy et al., 1991). The 1,300 cc and 10,000 cc OTR film treatments maintained a suitable oxygen content of greater than 5% (Kader, 2002).

Kader (2002) reported that a carbon dioxide concentration of 5-12% is better for asparagus spears kept in MAP storage. Our research shows that the carbon dioxide content increased rapidly during the first storage day and was proportionate to the oxygen transmission rate (Fig. 4B). The carbon dioxide content in the packaging was also proportionate to the oxygen transmission rate (Heyes et al., 1998). The highest carbon dioxide content was found in the V + 60% CO2 treatment, at greater than 60%, followed by the vacuum film (0 cc OTR) treatment. The lowest carbon dioxide content was found in the perforated and microperforated film treatments, and both were less than 2.5%. Compared with other treatments, the CO2 concentrations in the 1,300 cc and 10,000 cc OTR treatments were more suitable for asparagus storage.

Fig. 4.

Fig. 4. The change of gas contents in all of the packaging films. Oxygen (A), carbon dioxide (B) of green asparagus spears treated with the different films and methods. P, Perforated film; MP, micro-perforated film; 1,300 cc, 1,300 cc/m2/day/atm oxygen transmission rate (OTR) films; 10,000 cc, 10,000 cc/m2/day/atm oxygen transmission rate (OTR) films; V, vacuum film; V + 60% CO2, 60% CO2 injected into vacuum film, treatments storage for 20 days at 2°C. Vertical bars represent ± SE (n = 5).

Conclusion

Considering the acceptability of green asparagus in the consumers, visual quality, off-odor, texture, color are critical factors. Our purpose was to shed light on the effect of CO2 on the quality and shelf life of green asparagus during long period of cold storage. The results showed that MA packaging films were better for asparagus postharvest storage with the good sensory quality and long shelf life. And high CO2 treatment could retard the decline of soluble solids, inhibit respiration and the action of ethylene. To some extent, it can be used as the protector in asparagus postharvest storage. But the suitable concentration of CO2 and duration to green asparagus long-term storage should be evaluated.